ATEX COATINGS

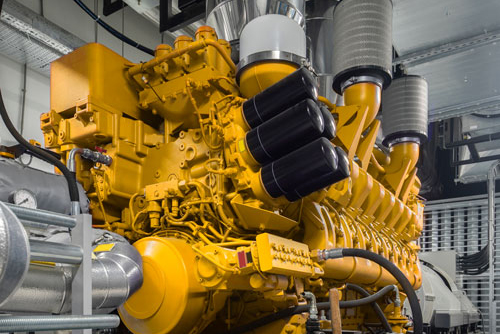

We offer special coating systems for hazardous areas in accordance with the ATEX Directive or TRGS 727 and EN IEC 60079:2018. These systems provide excellent corrosion protection and UV resistance. In addition, they have other properties that are required due to the special hazard potential in potentially explosive atmospheres. ATEX coating systems are specially designed for application on equipment, generators, motors, pumps as well as other machine components in areas with explosion hazards. They meet all the necessary requirements of the ATEX directive as well as the DIN EN ISO 12944:2018 standard. In addition, the use of our coating systems for hazardous areas gives you layer savings and maximum flexibility.

Our coatings have been tested according to the following standards:

- External testing of the system structure according to DIN EN ISO 12944:2018 Part 6 in accordance with the requirements of the corrosivity categories C2 high to C5 high

- External testing of the surface resistance of the coating systems according to

- EN IEC 60079-0:2018

- IEC TS 60079-32-1:2013

- IEC/EN 60079-32-2:2015

- TRGS 727 at 30% r.h. as well as at 50% r.h.

- EN IEC 60079-0:2018 Section 26.13 at 30% RH as well as at 50% RH.

ATEX-compliant systems externally tested according to DIN EN ISO 12944:2018 Part 6:

Coating thicknesses up to 200 µm with Remoplast UVC PL HS ES

High-performance polyurethane monolayer (corrosion protection classes C2 high and C3 high)

- Corrosivity category C2 high: Remoplast UVC PL HS ES: Monolayer NDFT 80 µm

- Corrosivity category C3 high: Remoplast UVC PL HS ES: Monolayer NDFT 120 µm

Due to the significant undercutting of the normative limit value of 200 μm, no normative requirements for the surface resistance have to be fulfilled

Coating thicknesses from 200 µm with Remoplast MSR Ultraprimer and Remoplast UVC HS ATEX

High-performance polyurethane 2-layer systems (corrosion protection classes C4 high and C5 high)

- Corrosivity category C4 and c5 high: Remoplast MSR Ultraprimer//REMOPLAST UVC HS ATEX = NDFT 120µm//120µm

- Externally tested according to DIN EN ISO 12944:2018 Part 6

- TRGS 727 at 30% r.h. as well as at 50% r.h.

- EN IEC 60079-0:2018 Section 26.13 at 30% RH as well as at 50% RH.